Claim Your FREE Guide

Make sleepless nights a thing of the pastwith this free guide to the benefits of latex

mattresses Simply spend a few seconds filling in your

details in the boxes on the right This is not an e-book!

we post it to you the old-fashioned way

Once you have filled in your details, be sure to check your email, as we will contact you

immediately to complete the process and arrange for your guide to be dispatched.

What are Dunlop and Talalay Latex?

Dunlop and Talalay are two methods for manufacturing the latex foam used in bedding.

Dunlop is the standard technology, developed in 1929, while Talalay is relatively new method which is more complex, costly and time-consuming.

Both methods use natural latex and can produce latex mattresses in any of the three blends described above.The production process always starts with mixing liquid latex with water. There are small amounts of other materials required for processing liquid latex into a solid form, which are necessary for all latex production. These are natural soaps, sulphur, and gelling and vulcanization agents. When the latex mixture is ready, compressed air is used to make foam. The foam is then poured into a mould, after which the vulcanization process begins. The latex foam is vulcanized at a temperature over 110 degrees for about 50 minutes. The finished mattress core is then taken out of the mould, washed and dried.

The key difference in processing in the Dunlop and Talalay methods is the two additional steps in the Talalay technology – vacuum and freeze. When the mould is filled with the latex mixture and then closed, the pressure inside is reduced to create a vacuum, which lowers the air pressure in the mould cavity while increasing the air pressure in the foam bubbles. As a result, the foam expands and fills the mould evenly and the pressure inside the bubbles is driven to equalize over the entire latex block, leading to a very uniform density. The water in the latex foam is then frozen and carbon dioxide is injected. The freezing prevents the latex particles from settling at the bottom and transforming into a solid product. This means that the finished Talalay latex mattress has very consistent density and from top to bottom. Because there is no freezing stage in the Dunlop process, the rubber particles settle in the bottom of the mattress while the liquid latex is gelling into its solid form and so there could be slight differences in the feel and the firmness of the two sides of a Dunlop latex mattress.Although the Talalay process takes four times longer and consumes five times more energy than the Dunlop process, the two additional process steps improve the feel, quality and consistency of the finished latex, but at high additional cost and also with a much bigger carbon footprint.

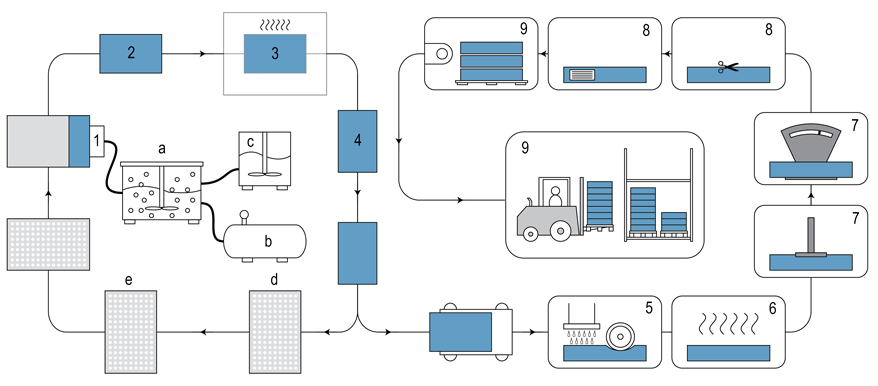

Dunlop Latex Manifacturing Process

a. The mixing of the ingredients (latex, soap, vulcanisation agents…) into compound

b. Compressed air (necessary to make a foam)

c. Continuous foamer

d. Cleaning and heating of the mould

e. Applying a special agent to be able afterwards to get the mattresses / pillows out of the moulds

1. Filling the mould with the latex foam

2. The mould closes and enters the vulcanisation oven

3. Vulcanisation oven: steam at 100ºC

4. The finished mattress / pillow core is demoulded

5. Washing of the mattress / pillow core

6. Drying

7. Quality control (checking hardness, weight, visual control)

8. Finishing

9. Storage

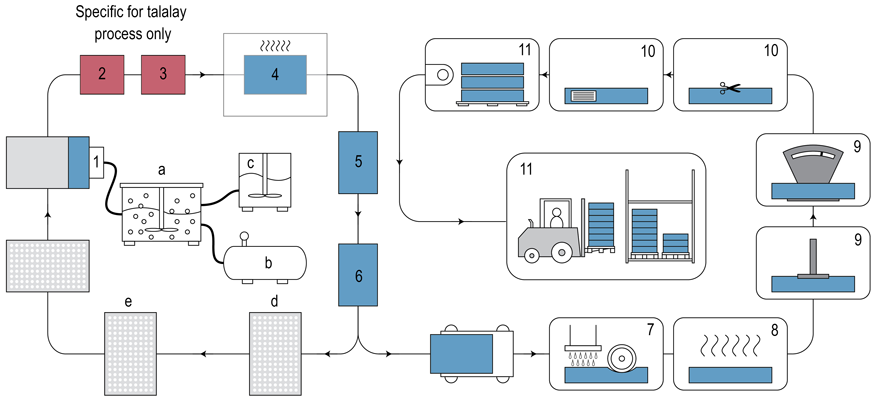

Talalay Latex Manifacturing Process

a. The mixing of the ingredients (latex, soap, vulcanisation agents…) into compound

b. Compressed air (necessary to make a foam)

c. Continuous foamer

d. Cleaning and heating of the mould

e. Applying a special agent to be able afterwards to get the mattresses / pillows out of the moulds

1. Filling the mould with the latex foam

2. Creating a vacuum (Specific for talalay process only)

3. Freezing to -30°C (Specific for talalay process only)

4. The mould closes and enters the vulcanisation oven

5. Vulcanisation oven: steam at 100ºC

6. The finished mattress / pillow core is demoulded

7. Washing of the mattress / pillow core

8. Drying

9. Quality control (checking hardness, weight, visual control)

10. Finishing

11. Storage

Read More:

- The Importance of Sleep.

- Choosing your comfort feel

- Chosing your thickness

- Organic Certified Latex Mattresses

- What is Latex?

- Why Latex?

- What are the different types latex?

- What are Dunlop and Talalay Latex?

- Which latex is better - Dunlop or Talalay?

- What firmness is right for me?

- Is Latex better than memory foam?

- Does my mattress need a topper?

- Choosing the right bed to go with your latex mattress.

- Guarantee on latex mattresses.

- Videos

- How Latex Is Made

- Free Guide to the Benefits of Latex Mattresses